Our objective is to ensure that you maintain your process at the desired operating conditions safely and efficiently, not compromising product quality. We even believe that proper use of process control makes your operation more reliable and more profitable.

We understand that your plants and processes are complex, and despite rapidly increasing computer speeds allowing high-performance measurements and control systems, it is not an easy task to achieve.

Ideally, you work with specialists, both having a background in chemical engineering as well as in control engineering. You find these at Chemploy.

How we work?

1. Obtain process understanding

It starts with process understanding. From here, our engineers obtain an understanding of process dynamics, usually described by differential equations. Identified unsteady-state process behavior then corresponds to a situation where time derivatives of the differential equations are nonzero. Such operations occur during start-ups and shutdowns, process disturbances, and product changeovers. If you look well, you will even see that at normal activities, your process does not operate at a steady state, e.g. due to variations in feed composition or in heating and cooling. As a matter of fact: the knowledge of steady-state process properties is not sufficient for proper control design. What is of importance is a deep understanding of your process and how it varies under the influence of possible variations, which is our starting point.

2. Definition of your system, setting up a control model

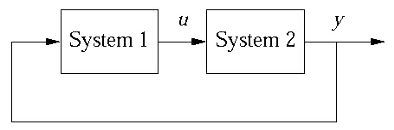

Once our engineers understand the processes sufficiently, they define control systems to handle changes in your process. They identify your system as a combination of components that act together to achieve a particular objective. Quite differently from chemical processes, the balance equations are defined by control inputs and outputs rather than material data. The control model is a set of equations used to predict the behavior of a system and can help determine what the response to change will be. The system of interest is usually decomposed into several subsystems that interact with each other, and every (sub)system interacts with its environment to 2 groups of variables: input and output variables that change over time.

3. Implementing control loops & feedback control

Conventional controllers we use are Programmable Logic Controllers (PLC) and Distributed Control Systems (DCS). Inputs/outputs come from HMI’s (if standalone) or Supervisory Control and Data Acquisition (SCADA). A fundamental aspect of your control system is the control loop, which controls one process variable. Some large systems may have several hundred or even thousands of control loops. In complex processes, probably yours too, the loops are interactive, so that the operation of one circuit may affect the operation of another circuit. That is where a feedback control system comes in place.

After the definition of your control system, your feedback control system is central to the automation systems we work with to monitor a process and adjust required variables to maintain your system at the desired conditions. Feedback occurs when two or more dynamical systems are connected such that each system influences the other. A consequence of this is that the behavior of feedback systems is often counterintuitive, and it is, therefore, necessary to use formal mathematical methods to understand them. Using feedback makes it possible to design systems that work in a desired way, even when, for some reason, the subsystems are not precisely known. Unstable systems are stabilized using feedback, and the effects or disturbances are reduced. It also increases flexibility.

4. The result

With this approach, a control system is set up that allows you to monitor your process and automatically make changes if the process requires so. Overall, you will obtain a process that is well understood, safe, and more profitable.